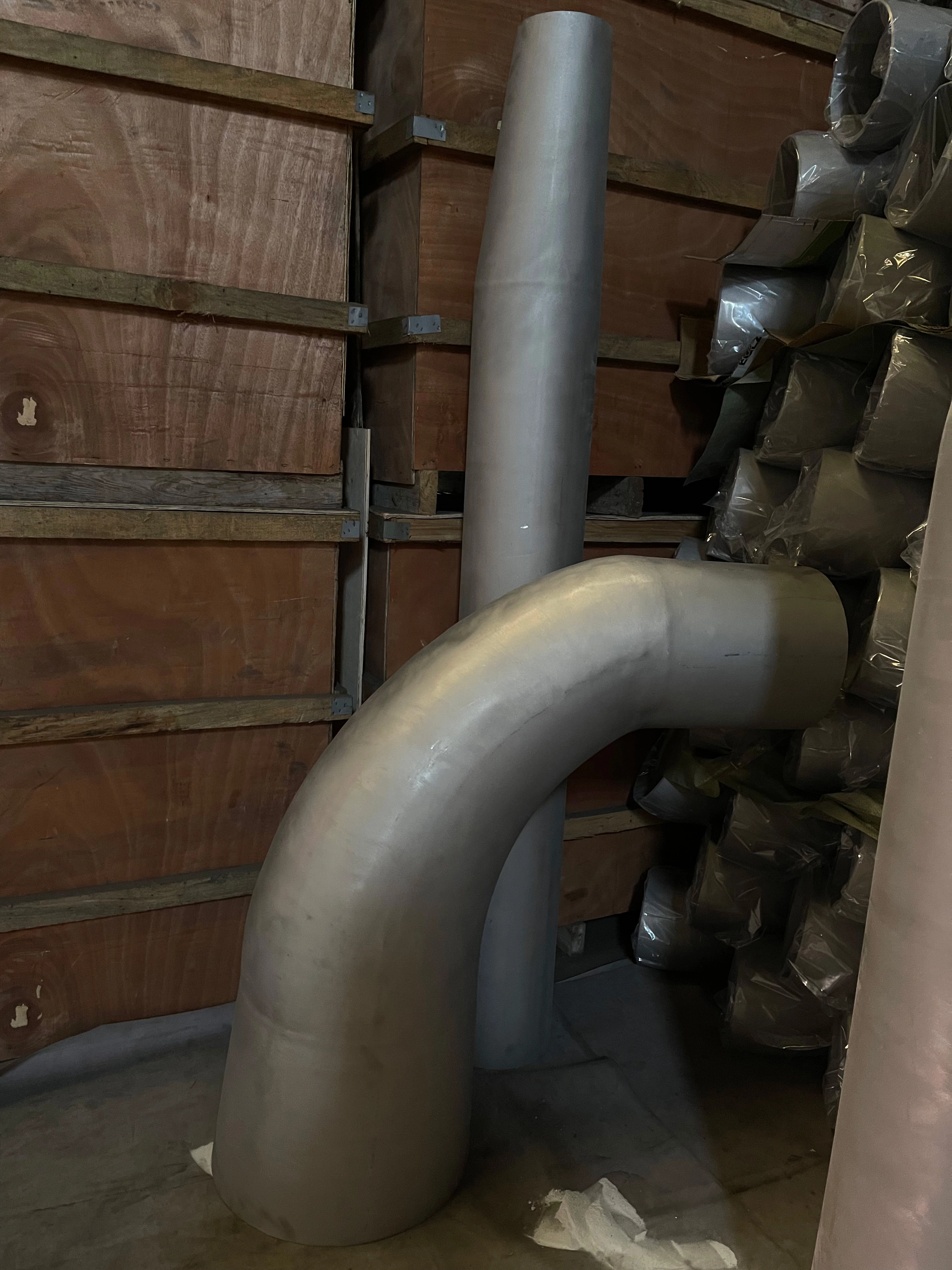

Deformation And Stress Distribution During The Production Of Stainless Steel Pipe Elbows

Stainless Steel Weld Elbow Deformation characteristics during bending

The deformation of stainless steel thin-walled elbows during bending is mainly manifested in the following aspects:

First, the inner and outer diameter deformations during bending are small. Due to its thin-walled structure, the inner and outer diameters of stainless steel thin-walled elbows will change during bending. It has been verified in practice that the inner diameter deformation rate of stainless steel thin-walled elbows is usually controlled within 2%, and the outer diameter deformation rate is usually controlled within 4%.

Second, the cross-sectional shape changes during bending are small. Stainless steel thin-walled elbows are subjected to tensile and compressive forces during bending, causing their cross-sectional shape to change. However, due to the excellent performance of its material, the cross-sectional shape of stainless steel thin-walled elbows changes little and can maintain a good fluid channel.

Stress distribution during bending of stainless steel pipe elbows

During the bending process, the pipe wall of stainless steel thin-walled elbows is subjected to stress, and its stress distribution characteristics are as follows:

First, the stress concentration area generated during bending is at a distance of 1.5 times the bending radius. The larger the bending radius of the stainless steel thin-walled elbow, the smaller the distance between the stress concentration area and the bending radius.

Secondly, the stress distribution during the bending process is symmetrical. During the bending process, the stress distribution of the inner and outer diameters of the stainless steel thin-wall elbow is symmetrical. This symmetrical feature can ensure the stability of the pipeline system and the smooth flow of the fluid channel.

The stress change rate generated during the bending process is large. During the bending process, the stainless steel thin-wall elbow has a large stress change rate due to the tensile and compressive forces. In order to ensure the safe operation of the pipeline system, the stress during the bending process must be fully calculated and controlled.